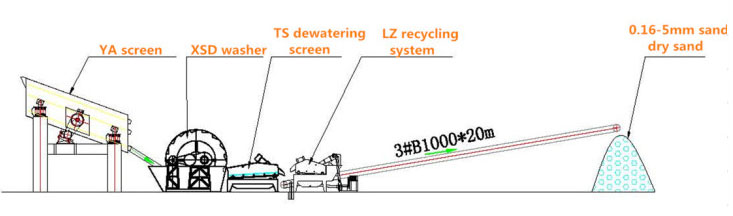

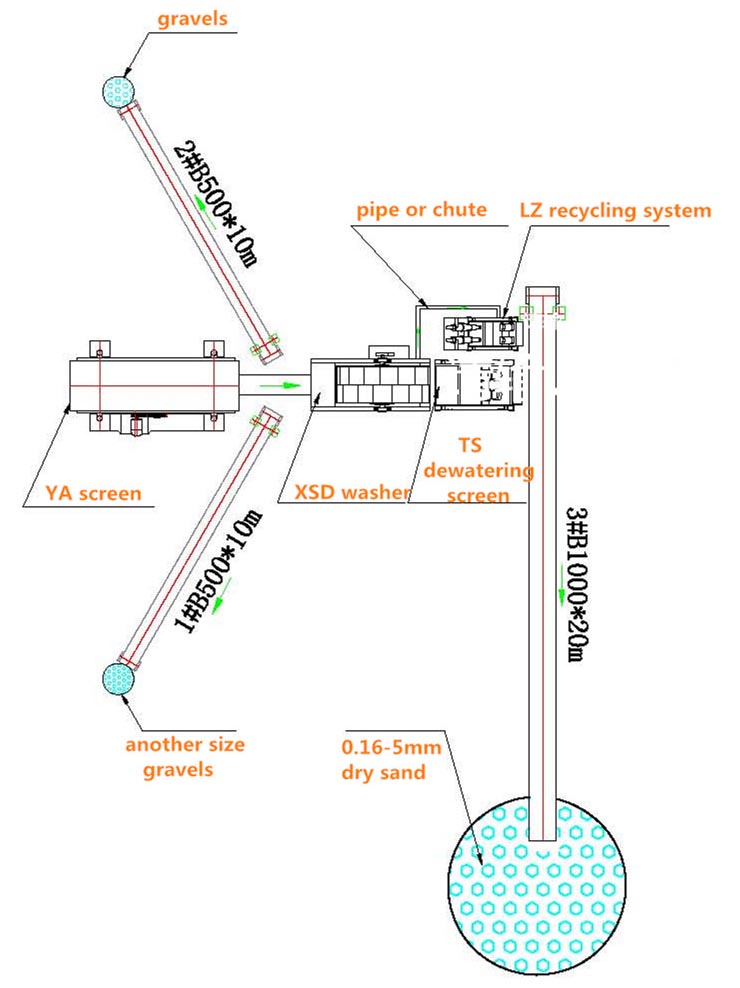

100-120t/h river sand production line

River sand is a kind of common sand at ordinary times, so it is a main material for producing construction sand in the market. Then how is the river sand processing plant?

100-120t/h Sand screening, washing , recycling and dewatering equipment

Vibrating screen : 3ya1548

Sand washer : XSD3016 / 2 set

Dewatering screen : TS1530

Sand recycling machine : LZ550

Vibrating Screen : 3YA1548

The YA River sand vibrator screen is used to separate the stuff. It is composed of main frame, screen web, electric motor, eccentric bock, rubber spring, coupler and so on .We will offer suitable type according to your requirements. ZSG series of linear vibrating screens are widely applied to screen dry materials in Concentrator, building materials, water and power, light industry and building materials.

XSD series sand washer : XSD3016

XSD Construction sand cleaning washer is a kind of bucket sand washing machine that coordinates with sand making machines. It can wash out the small amount of the sand powder and impurities from the mixed sand to improve the sand quality. This machine is developed by adopting advanced technology with the consideration of the current situation in sand industry, which is used in washing and selecting, classifying and dehydrating in building, sand plant, hydropower, and glass factory.

Dewatering screen : TS 1530

We absorbed foreign advanced technology and its designing is combined with sand filed actual situation, it possess the international advanced level, widely used in mud purification, artificial sand production line, hydropower station and sand aggregate system, glass raw material processing system and coarse slime recovery, and fine material recovery.

Sand recycling machine : LZ550

We absorbed foreign advanced technology and its designing is combined with sand filed actual situation, it possess the international advanced level, widely used in mud purification, artificial sand production line, hydropower station and sand aggregate system, glass raw material processing system and coarse slime recovery, and fine material recovery.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.