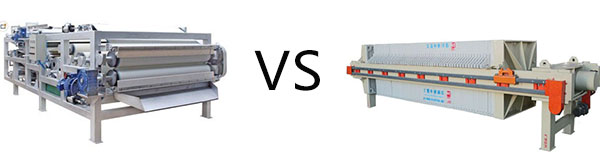

Belt press vs Filter press

Belt press and filter press are the most commonly used sludge dewatering equipment, which are to reduce the moisture content of sludge, sludge volume, so as to achieve dry sludge discharge. They are widely used for the filtration separation of solid-liquid mixture produced in muddy water, urban sewage treatment, food processing, petrochemical, metallurgical manufacturing, mining, metal forging, pharmaceutical and pharmaceutical, electronics, chemical and other industries.

Belt press vs filter press

Basic overview

Belt press is a device for constructing solid-liquid separation by the tension of track. The dehydration process can be divided into four important steps: pretreatment, gravity dewatering, wedge zone pressure dewatering and press dewatering. Conducive to materials with dissolved taste or gas, bright flow exhaust liquid.

Filter press is a machine that takes pressure from pump to build solid-liquid separation, which is widely used in sludge dewatering projects in Europe and America. The filter plates and filter frames are arranged into a filter chamber, and under the pressure of feed pump, feed liquid is sent to each filter chamber, and the solid medium and liquid are separated by the filter medium.

Working manner

Belt press: continuous dewatering

Filter press: Intermittent dehydration

Working process

The main difference: filter power

Sludge dewatering belt press is composed of a sludge layer sandwiched between upper and lower tensioning belts, and passes through a series of regularly arranged roller cylinders in an S shape, and relies on the tension of filter belt itself to form a squeeze layer on the sludge layer. The pressing and shearing force squeezes out the capillary water in sludge layer to achieve sludge dewatering.

Filter press is an intermittent solid-liquid separation device. The sludge pumped by high-pressure pump is squeezed through the plate frame, so that water in sludge is discharged through filter cloth to achieve the purpose of dehydration. At the same time, it is also possible to carry out the solid-liquid separation of the mud cake, such as washing, damp and other auxiliary processes. The airtightness is very good and it is possible to construct an undercurrent exhaust gas.

Application

Belt presses are generally used in sludge dewaterning treatment, large sewage treatment plants, waterworks, etc.

Filter presses are generally used for sludge dewatering in mining, especially for where required high dewatering effect, to reduce sludge volume and reduce post-treatment costs.

Advantages and disadvantages

Belt filter press advantages:

1. large processing capacity, high dewatering efficiency

2. Running continuously, easy management;

3. Long service life, low auxiliary equipment and low energy consumption.

Belt filter press disadvantages:

1. Large amount of flocculant used together, high operating cost;

2. Large water content of mud cake than chamber filter press.

Chamber filter press advantages:

1. Filter cake has a low moisture content and generally does not exceed 30%;

2. High solid content;

3. Less flocculant used.

Chamber filter press disadvantages:

1. Work efficiency is relatively low because of the intermittent operation;

2. Need to change the filter cloth regularly.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.