How to select dewatering screen in correct way

When looking for a dewatering screen suitable for your project, you should get to know more about the main parts of product.

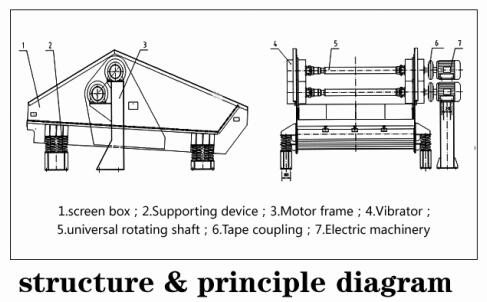

Dewatering screen is consisted of screen box, vibrator, supporting device,motor,etc. (Structure show as below)

1.Screen box

Screen box is main working and components bearing. The screen frame need to be strength enough, rigidity and wear resistance. So the components are required connected sturdily and steel material is light as much as possible. LZZG applies matching material for welding, Q235 steel plate, which has features of simple manufacturing process, light weight, reliable working, etc.

2、Screen surface

Screen surface is main part of dehydrating process, the quality of structure is direct impact on dewatering result.

LZZG adopts laminated composite screen which is laminated together by different sieve size stainless steel mesh, the first level of sieve is surround by Polyurethane Rubber. It extends the service time of sieve. As to the different diameter of wire, it prevent the blockage of sieve when working.

Sieve pore is 0.16-0.2 for your option.

3、Vibrator

Preferably rational layout and structure of parts is very important. LZZG vibrator of dewatering screen adopts external vibrating motor eccentric block, both sides of screen are lay out group of exciter, two set of bearings per group of exciter.

4 、Rubber spring supporting

Due to the vibrating screen is working at high frequencies (25Hz-50Hz), supporting structure influences greatly on working characteristic, Cylindrical rubber shear spring is best choice.

The advantage as below:

Size, shape, rigidity can be freely selected.

Can withstand large elastic deformation.

Easy to install and replace

Long term using.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.