Overview

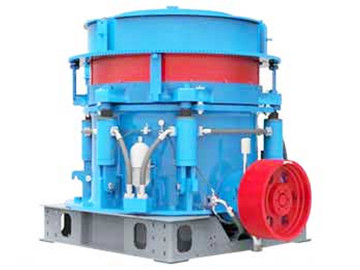

HP series hydraulic cone crusher is widely used in mining cement, sand stone industry. As secondary and tertiary crusher, it is crushing all kinds of stones, like ore, metallic rock, bauxite, quartz, asalt and limestone.

-

Working principle

When the cone crusher is working, the motor rotates through the pulley or coupling, the transmission shaft of the cone crusher and the conical part of the cone crusher rotate around a fixed point under the forced action of the eccentric sleeve.

The crushing wall of cone crusher sometimes gets close to and sometimes leaves the surface of mortar wall fixed on the adjusting sleeve, so that the ore is continuously impacted, squeezed and bent in the crushing chamber to realize the crushing of ore.

-

Features & Benefits

1. New type HP series hydraulic cone crusher is equipped with insurance cylinder, lock cylinder and promotion cylinder, which not only play the role of insurance equipment, but also can solve mechanical problems without opening the machine.

2. It can adjust room of the outlet, easy to operate and reliable.

3. The chamber is designed with the principle of lamination. In accordance to the rotating speed, it can improve the crushing ratio and capacity, and increase the content of cubic products.

4. When iron feeds into the chamber or there is a sudden stop, the machine can lift the roof automatically, and discharge the material, which largely reduces the trouble of discharging by man. It is easy to maintain and low cost.

5. Hydraulic adjustment and oil lubrication and efficient labyrinth seal radiate the problem of oil-water mixture.

6. The concave and mantle are made of high manganese steel. With the change of cavity type and the protection of material layer, it greatly reduces the wear and its service life is longer than the old cone crusher by 35%-82%.

-

Specifications

Model Cavity (coarse/fine) Min discharge setting(mm) Feed opening(mm) Capacity(t/h) Power(kw) Weight(t) Movable cone diameter(mm) HP-160 C 13 150 120-240 160 13 950 F 6 76 55-180 HP-220 C 13 225 150-430 220 18 1160 F 6 86 90-260 HP-315 C 13 290 190-610 315 26 1400 F 6 100 108-320 HP-400 C 13 320 230-700 400 33 1500 F 6 110 145-430 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry