Overview

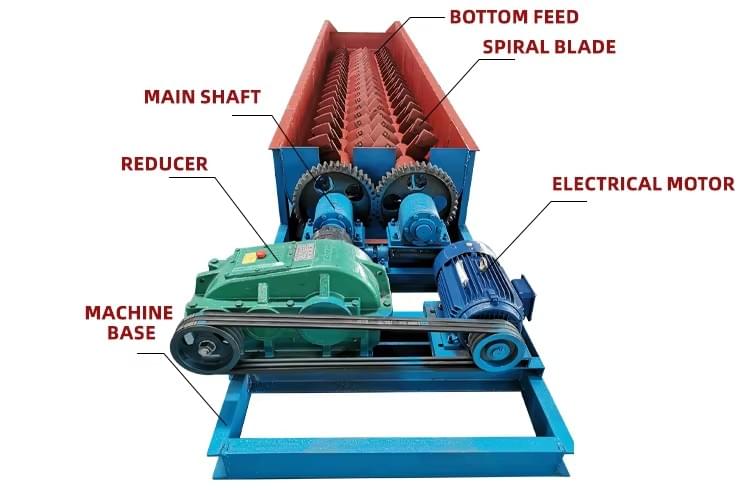

Log washer is used for washing various easily washable and difficult washable ores. Log washer can achieve the separation of ore and mud by spiral stirring and scrubbing ore containing more than 20% mud in the washing machine.

Log washer is suitable for desilting tasks of sand and gravel in construction sites, sand and gravel plants, concrete prefabrication plants, and water and electricity construction sites. It can also be used for ore washing, grading, and dewatering.

-

Working principle

The motor drives the reducer, and the large and small gears drive the cleaning cylinder to rotate at low speed. The aggregate containing mud lumps and stone powder is fed into the feeding port and enters the rotating mixing blade. The cleaned mixing blade is equipped with a rubber lining plate at a certain angle, which continuously lifts and throws it off.

During the scrubbing process, the material moves from the feeding end to the discharging end in multiple cycles and is washed by forward or reverse flushing water. The cleaned aggregate is sieved and dehydrated at the discharging end before being discharged. Wastewater containing sludge flows out through perforated baffles at the discharge or feed end.

-

Features & Benefits

The log washer has a long spiral body, good sealing system, and simple structure. The rotation directions of the two spirals are opposite, and the upper blades rotate outward. This structure enables the trough washing machine to have strong cutting and scrubbing capabilities.

The processing capacity is usually between 10-70t/h, depending on the equipment model and ore properties. The sand has low moisture and mud content.

Log washer can avoid clogging of crushing and screening equipment with mud materials containing mud minerals. If the raw materials contain soluble useful or harmful components, they should also be washed.

The combination of log washer and rotary scrubber is an effective means of handling difficult to wash ores.

-

Specifications

Model Spiral Dia. (mm) Rotating Speed (r/min) Feeding Size (mm) Tank Slope (o) Output (th) Power (Kw) Weight (t) 2LZXL320 Φ320*3200 28 ≤30 ≤12 10 4 0.9 2LZXL400 Φ400*4600 23 ≤30 ≤12 20 5.5 1.9 2LZXL540 Φ540*4600 23 ≤30 ≤12 25 7.5 3.9 2LZXL750 Φ750*7600 22.7 ≤70 ≤12 50 11 7.5 2LZXL800 Φ800*7600 22 ≤70 ≤12 70 15 9.5 2LZXL914 Φ914*7600 21 ≤70 ≤12 100 22 12.9 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry