Overview

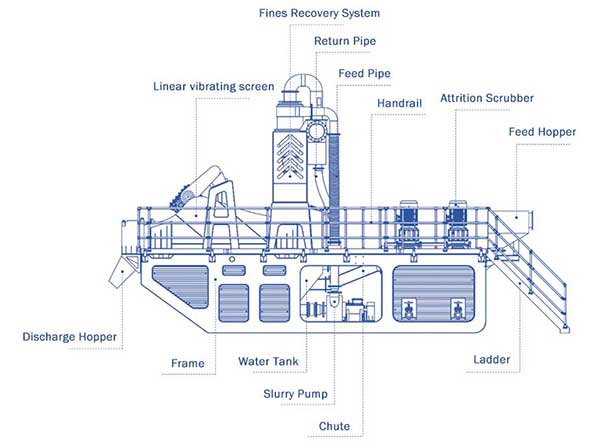

Ultra sand wash plant is the ideal choice for customers to perform washing, grading, scrubbing, purification, and dewatering of sand and gravel aggregates.

Ultra sand wash plant is designed to efficiently remove excess fines or coarse sand in a simplified manner. Ultra sand wash plants adopt an integrated structure, and the solid frame protects the internal precise transmission system, efficient cleaning components and intelligent control system. These ingenious structural designs improve cleaning efficiency and reduce maintenance costs.

Ultra sand wash plant is suitable for diverse applications, including washing natural sand/machine-made sand, construction sand, foundry sand, silica sand, frac sand, as well as recycling materials and construction waste. LZZG ultra sand wash plant can be customized to meet specific requirements for sand and gravel plants.

-

Working principle

The mixed materials first enter the scrubber for thorough friction washing, then flow into the screen water tank via a chute. The initially washed slurry is pumped into the hyddrocyclone, where centrifugal force further cleans and dewatering is achieved, separating mud and sand.

The hydrocyclone underflow enters the coarse sand dewatering zone of the linear screen for dehydration, while the overflow material returns to the water tank through the reflux pipe for cyclic cleaning and water replenishment, thereby ensuring efficient washing.

-

Features & Benefits

1.Equipped with efficient transmission device.

2.High efficiency, large processing capacity, durable, energy saving and environmentally friendly.

3.Intelligent control. Equipped with PLC control system to realize flow control and liquid level control technology.

4.The cyclone shell is made of 8mm thick steel plate, the inner lining is made of 95 wear-resistant ceramic material, which is strong and durable.

5.The side panels of the dewatering screen are updated with a cloud-like design concept.

6.All flow-through parts are sprayed with wear-resistant polyurethane material, which increases the service life of the whole equipment. 3-year warranty on wearing parts.

7.The maximum size of the components is designed according to the container and can be packed and shipped to all parts of the world.

-

Specifications

Model Capacity(t/h) Scrubber Spec (mm) Hydrocyclone (mm) Screen Spec (mm) XS50 50 CX2-1 550 1530 XS100 100 CX2-2 660 1848 XS150 150 CX3-1 710 2448 XS200 200 CX3-2 2*660 3060 XS250 250 CX4-1 2*660 3660 XS300 300 CX4-2 2*710 4272 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry