Overview

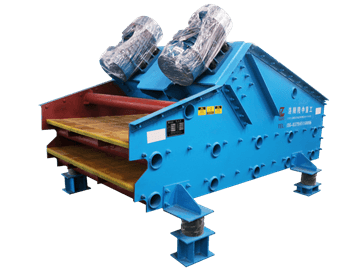

The double deck dewatering screen overcomes the shortcomings of the existing dehydration technology. On the basis of the original dewatering screen, not only the dewatering intensity is strengthened, but also the handling capacity is also increasing, and the screening accuracy is also relatively improved.

The division of screening and dewatering between the upper and lower screen panels of the double deck dewatering screen can not only ensure the quality of materials, but also meet the different gradation needs of customers.

-

Working principle

Double Deck Dewatering Screen adopts dual-motor self-synchronization technology.The motors coordinate with universal eccentric and adjustable amplitude vibrator. When the two motors start to work, the vibrators move reversely at the same time. The centrifugal force is generated by the eccentric blocks superpose themselves and form a single direction vibration. The high frequency vibration drives the screen move back and forth in line repeatedly. So the sand will be dehydrated and filtered.

-

Features & Benefits

1.Choose polyurethane screenas its vibrating screen.

2.Customized sizes.

According to different situation, not only polyurathane screen mesh can be adjustable,

but also its length, width and screen layers can be manufactured for different needs.

3.Simple structure, easliy installation and lower invest.

4.Bending a whole steel plate as its main body, no welding and no leaking.

5.Final sand water content down to 15%, convenient in packing and delivery. -

Specifications

Model Screen area (m²) Power (kw) Capacity (m³/h) Feed size (mm) Weight (t) Overall dimension (L*W*H)(mm) TS1020 2 1.5*2 20-30 ≤10 1.6 2220*1340*1190 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry