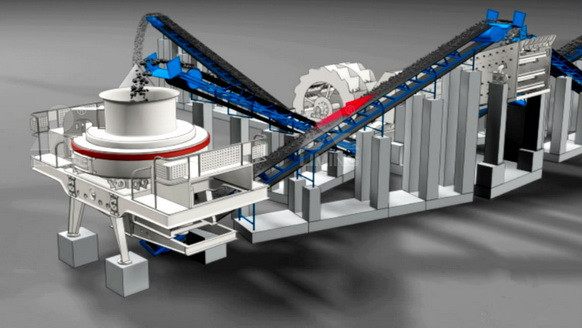

Mechanism sand production process

The mechanism sand production process mainly includes 7 systems: feeding–coarse crushing–fine crushing–grading–dust collecting– sand washing and cleaning–transporting. This is the wet production process, including the main equipment such as hopper, vibrating feeder, jaw crusher, impact crusher, sand making machine, vibrating screen, dust collector, sand washing machine, belt conveyor and more.

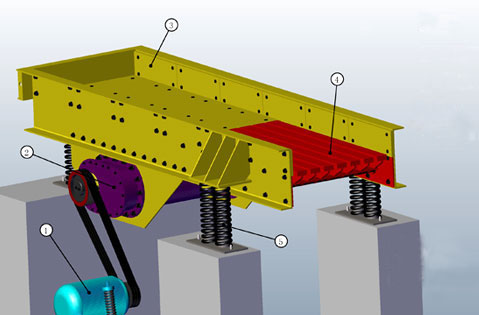

1. Technical requirements for vibrating feeders

Vibrating feeder is between the hopper and jaw crusher. It can feed the block and granular materials uniformly, regularly and continuously from the hopper to receiving device, and coarsely screen the materials.

According to the performance requirements, the design should be:

A. Try to reduce the pressure of material on the tank. Generally, the effective discharge of hopper should not be greater than 1/4 of the width of tank. The flow speed of the material is controlled at 6~18m/min.

B. For materials with a large amount of feed, the barrage plate of the height should be set at the bottom discharge of the silo, but the barracks should not be fixed on the trough.

C. In order to make the materials discharge smoothly, the back wall inclination of hopper can be designed to be 55~65°.

2. Selection of crushing equipment

In the production process of mechanism sand, a three-stage crushing process is generally adopted, that is, coarse crushing, medium crushing, and sand making. The crushers used in different crushing stages are also different. In the coarse crushing, jaw crusher is commonly used; in the middle crusher, impact crusher is generally used; and the sand making machine is generally dominated by impact crushing. The performance of various common crushers is as follows:

|

Crusher type |

Broken method | Movement mode | Crushing ratio | Crushing application | Material type |

|

Jaw crusher |

Mainly squash | Reciprocation | 4-6, medium broken up to about 10 | Coarse and medium |

Hard |

|

Cone crusher |

Mainly squash | Rotation | Coarse crushing 4-6,medium, fine 3-17 | Coarse, medium and fine |

Hard |

|

Roller crusher |

Mainly squash | Rotation(slow) | 3-8 | Medium and fine |

Hard, soft |

|

Hammer crusher |

Impact | Rotation(quick) | Single rotor 10-15, double rotor about 30 | Medium and fine |

Hard, soft |

| Impact crusher | Impact | Rotation(quick) | >10, up to about 40 | medium |

Hard |

3. Effects of vibrating screen on the mechanical sand production

The main influencing factor of mechanical sand grading is the screening process. The shape and size of screen and the inclination angle are the key parameters affecting the quality of mechanism sand.

A. There is a large amount of stone powder particles in the production of machine sand, and the requirements for grading are relatively high. It is not suitable to use rectangular and circular sieve holes, generally adopting square square hole sieve.

B. The choice of mesh size directly affects the quality and throughput of mechanism sand. Studies have shown that the larger the screen size, the larger the fineness modulus of sand produced, and the lower the stone powder content; the smaller the screen size, the smaller the fineness modulus of sand produced, and the larger the stone powder content. According to relevant research, the recommended mesh size in general sand making process is 3.5-4.5mm.

C. In order to achieve better screening efficiency and throughput for the material, according to the experience of vibrating screen manufacturer, the inclination angle of sieve surface is generally about 20°.

4. Mechanism sand washing machine selection

There will be 10% to 20% of stone powder (<75μm particles) in the production process of the mechanism sand. Appropriate amount of stone powder can improve the defects of poor workability of mechanical sand concrete and increase the compressive and flexural strength of concrete. However, if the content of stone powder is too high, it will affect the performance of the mechanism sand concrete, so it is necessary to remove the powder from the mechanism sand.

The powder removal process of mechanism sand is the key to controlling the content of sandstone powder. It is required to meet the requirements of different grades of concrete and to have a small impact on grading. The wheel sand washer or screw sand washer is recommended to remove the powder.

Previous:none

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.