What’s the Difference Between Plate and Frame, Chamber, and Membrane Filter Press?

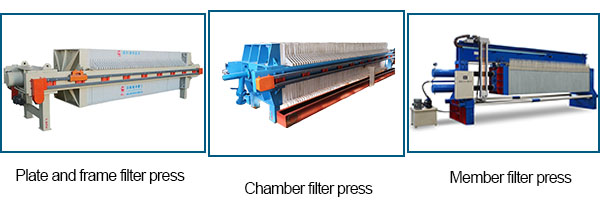

Filter presses have a wide variety of types and models. The common filter presses on the market are plate and frame filter press, chamber filter presses and membrane filter presses according to the current sludge treatment requirements. So what is the difference between these three filter presses?

In brief

Simply speaking, plate and frame filter presses, chamber filter presses, and membrane filter presses are all plate and frame filter presses.

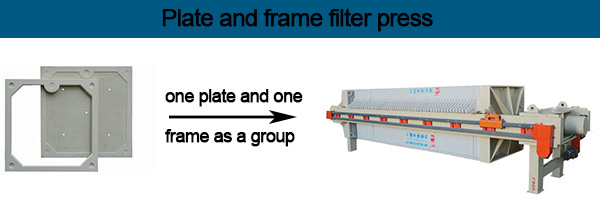

1. Plate and frame filter press–one plate and one frame as a group, is the oldest type

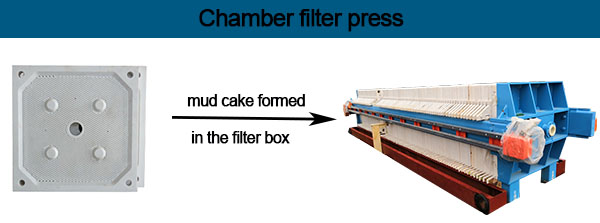

2. Chamber filter press–mud cake formed in the filter box

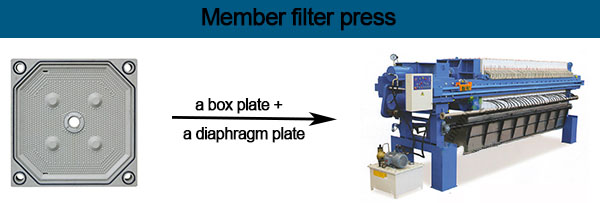

3. Membrane filter press–a box plate + a diaphragm plate

As for the machine form, there are three types: vertical, high cantilever, and side bars. This is related to how the filter board is linked to the machine.

Whether the fully automatic plate and frame filter press, fully automatic chamber filter press or high pressure diaphragm filter press, the working principle of theirs all pressure filtration, which is the same working principle of filter press. The essential difference between plate and frame filter press, chamber filter press and diaphragm filter press is that the differences in filter plates used. Through the filter plate to distinguish which kind of filter press, according to the use of requirements to choose the filter press.

In the professional

Different filter plate structure

The filter chamber of plate and frame filter press is formed by interlacing two kinds of filter plates, a solid filter plate and a frame filter plate. Each filter press has a different number of plate frames depending on the size of area. Plate and frame filter presses are generally used for material filtration with less granular objects and fine products.

Chamber filter press is composed of two identical filter plates to form a filter unit. When the two filter plates are pressed together, a filter chamber is formed for storing the granular objects separated by the filter cloth. The feed hole is placed in the center of filter plate. The single filter plate is thicker than the plate and frame filter plate. Generally used for materials with more granular objects, such as sewage treatment, mineral processing, coal washing, etc.

The filter plate used in membrane filter press has a diaphragm cavity on both sides. There will be inlet holes on the side of filter plate. It’s hollow in the middle, and it’ll pop up when it’s inflated. The plate and frame filter press and diaphragm filter press do not have this function, which is very different.

Different press cloth styles

The plate and frame filter press filter cloth is a square filter cloth, which can be directly placed between the filter plates.

The diaphragm filter press applies two filter cloths connected in the middle to form a filter cloth unit. One of the two layers is passed through the middle hole of the filter plate and then flattened to wrap the filter plate.

Different filter cavity formation

The filter chamber of plate and frame filter press requires two solid filter plates plus a frame filter plate. The diaphragm filter press consists of a solid filter plate and a hollow filter plate.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.