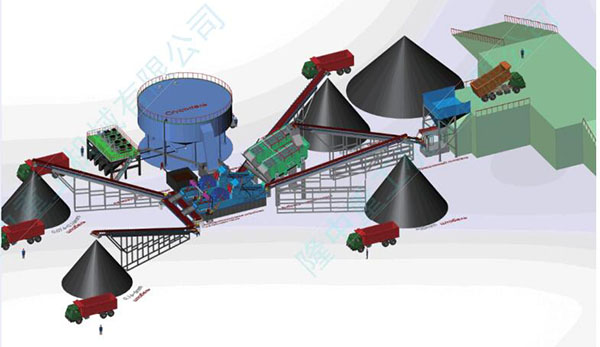

Gravel washing plant in Indonesia

Gravel washing plant in Indonesia is widely used to produce raw materials for construstion, highway, railway construction, water conservancy engineering and metallurgical industry. And sand and gravel plant can have a variety of design and configuration schemes according to different materials and output, and there will be some design differences according to different terrain. So whether you require an individual piece of equipment or a gravel washing plant, based on yor requirements, we will develop the specific solution coupled with the details of how our equipment can help you address the issues you are facing now.

LZZG have been engaged in the construction of gravel plant for decades, and have lots of experience of the construction of sand and gravel plant. We can build washing lines of various output of 20 to 200 tons per hour, which not only has reasonable design, low maintenance cost and durable equipment, but also has a good reputation among users in the mining industry. And LZZG gravel washing plant can maximize equipment service life, maximize resource yield and minimize waste.

Five systems of gravel washing plant

1. Feeding system

Feeding system is the beginning of a gravel washing plant, which is usually completed by vibrating feeder, to conveying and supplying raw materials to the following equipment.

2. Screening and conveying system

Screening system is a grading process that classify raw materials through vibratingscreen. In the sand and gravel washing line, different particle size sand and gravel need to be separated, and the graded products need to be transported to their respective fields.The equipment used in this process is usually linear vibrating screen and conveyor belt.

3. Washing and dewatering system

Washing system is refer to a cleaning process finished by sand washing machine, which mainly wash out the impurities mixed in sand to get the purpose of clean sand. Dewatering screen is adopted for dewatering system, which realize the dewatering purpose through the vibration of screen, the water content of finished proucts down to 12%-15%.

4. Fines recycling system

The fines recycling is usually processed by desander cyclone, which can recover 0.074-3mm fine sand by the centrifugal force.

5. Muddy water purification system

Muddy water purification system is composed of deep cone thickener and belt press. The water can be reused and mud realize dry discharge through this system.

Some of the issues this sand and gravel washing plant can settle

1. Finished products are too dirty to meet nationl standard

2. Finished products are too wet to sell directly

3. Recycling more than 95% fines to improve product capacity and reduce economic loss

4. Recycing of waste water that used in this process for recirculation

5. Mud realize dry discharge

6. Reduce the use of settling ponds

7. Reduce environmental pollution

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.