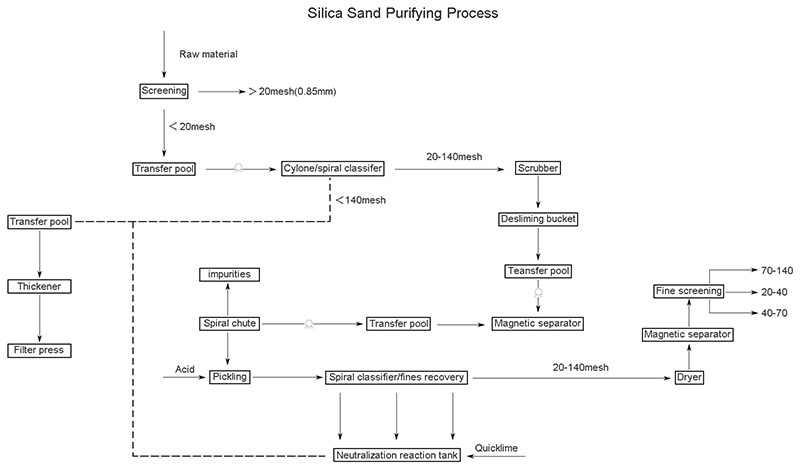

LZZG 20-140 Mesh Quartz Sand Process

The quartz sand process is a separation technology used to remove small or trace impurities in quartz sand to obtain refined quartz sand or high-purity quartz sand. It mainly includes the impurity removal process of quartz sand, the purification process of quartz sand, the classification process of quartz sand, etc. The quartz sand production line is mainly composed of a vibrating screen, spiral classifier, scrubbing machine, magnetic separator, spiral chute, pickling machine, dryer, linear screen, thickener, filter press, and other equipment. Different equipment is combined to meet different process requirements.

Quartz sand process

1. Quartz sand removal process

A. Crushing, grinding, coarse sieving

The natural quartz sand is crushed into small pieces with a crusher, and then wet grinding is performed with grinding equipment to grind the small pieces of quartz into finer-grained quartz sand. The wet grinding process can not only eliminate the dust generated in the grinding process, but also make the quartz particles rub against each other, and promote the dissociation of the impurities attached to the quartz surface from the quartz particles. Then the grinding product enters the classification process. The coarse particles >20mu are returned to the grinding equipment for regrind, and the quartz sand <20mu enters the transfer pool for preliminary impurity removal and cleaning.

B. Grading

The quartz sand particles after preliminary removal of impurities in the transfer pool enter the cyclone or spiral classifier for classification. The output of the cyclone or spiral classifier is 20-140 mesh quartz sand, and then it enters the scrubbing machine. The fine-grained quartz sand of <140 mesh enters the sewage transfer tank along with the tailwater, and then is pumped into the thickener. Under the action of gravity and flocculant, the solid particles settle and enter the filter press to press out the mud cake to achieve dry discharge. The clean water from the upper part is reused.

C. Scrubbing

The mechanical force of the scrubber and the grinding and peeling force between the sand grains can remove the thin-film iron, bonding, and muddy impurity minerals on the surface of the quartz sand, and further smash the unconsolidated mineral deposits. The material discharged from the scrubber enters the desliming hopper for further desliming. The tailwater returns to the cyclone or spiral classifier to continue classification. The solid quartz stone particles enter the transfer pool.

D. Magnetic separation

The pump sends the quartz sand in the transfer tank to the magnetic separator for iron removal. Magnetic separation is an effective method to remove iron-containing impurities in raw materials. The weakly magnetic hematite, limonite, biotite, and other minerals contained in the raw materials can be selected by a wet strong magnetic separator. For the strong magnetic minerals dominated by magnetite, the weak magnetic separators or medium magnetic separators can be used for separation.

E. Gravity separation

After the finished product of the magnetic separator is transferred and settled in the transfer pool, the upper particles enter the spiral chute. Under the action of centrifugal force, impurities with a specific gravity greater than quartz are removed.

2. Quartz sand purification process

A. Acid leaching

The discharge from the spiral chute enters the pickling machine, where acid is added for pickling. Soak, stir, remove powder and impurities.

B. Classification, recycling

The acid-washed quartz sand adds water to the spiral classifier or recovery machine. Under the action of the centrifugal force of the spiral classifier or cyclone, the solid particles of 20-140 mesh are recovered, and then discharged into the dewatering screen to dehydrate to 12%-15%. The tailwater is discharged into the neutralization reaction tank, and quicklime is added to adjust the PH value, and then returned to the sewage transfer tank, and then enters the thickener and filter press to achieve dry tailings discharge and clean water reuse.

C. Drying

After being dehydrated by the dewatering screen, it enters the dryer for drying treatment. The moisture content of the dried quartz sand is less than 10%.

3. Quartz sand classification process

A. Grading

The dried quartz sand enters the dry magnetic separator again to remove iron. Then enter the classifier to enter 20-40 mesh, 40-70 mesh, and 70-140 mesh finished materials.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.