Sand and gravel wash plant is a special production line for the production of construction sand and stone. The sand and gravel wash plant is defined according to the type of discharge. The finished pr…

read more >>

Sand washing machinery for concrete is widely used to reduce mud content of sand in building materials, metallurgy, urban construction, highways, highways and other construction. No matter natural san…

read more >>

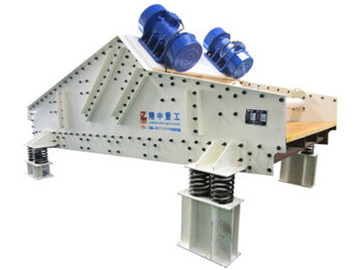

The dewatering screen sizing is mainly used to process the screening and classification of granular materials of different sizes. The vibrating dewatering screen sizing can be divided into different c…

read more >>

The sand washing classifier machine is a sand washing equipment specially developed for the production of high-quality sand and gravel. The sand washing classifier machine is easy to operate and maint…

read more >>

When screening wet viscous materials, the normal operation of the vibrating screen is often affected by the blockage. Because the wet fine-grained viscous materials stick to each other into agglomerat…

read more >>

The basic working part of coal washing and screening equipment is the screen surface, on which there are screen holes of a certain shape and size. Generally, two products can be obtained on one screen…

read more >>

Stone washing machine for sale Sri Lanka mainly washes various granular materials over 5 mm, such as crushed stone, pebbles, coal, ceramic particles, etc., especially the stones with large stone powde…

read more >>

The limestone crushing production lines are very common in the crushing and sand making industry, with an hourly output ranging from 100t to thousands of tons. Limestone is often used as a building ma…

read more >>

The screening efficiency and screening effect of the drum screen are directly related to correct operation and daily maintenance. Although there is no complicated structure, such as magnetic separator…

read more >>

The operation of the linear vibrating screen is related to many aspects, including the equipment's own technical parameters, whether the operation is standardized and regular maintenance. What is the …

read more >>

The filtering principle of sludge dewatering machine filter press is a process for separating solid particles suspended in liquid or gas. The sludge treatment needs to go through three main links: pre…

read more >>

Tailings dewatering is a new tailings disposal technology that has gradually emerged in recent years. It means that the tailings slurry output by the beneficiation process is concentrated in multiple …

read more >>Copyright © 2015 - 2025 Luoyang Longzhong Heavy Machinery Co., Ltd. Website Map | Privacy policy | Contact Us

Inquiry