Sand Washer Machine Layout Plan

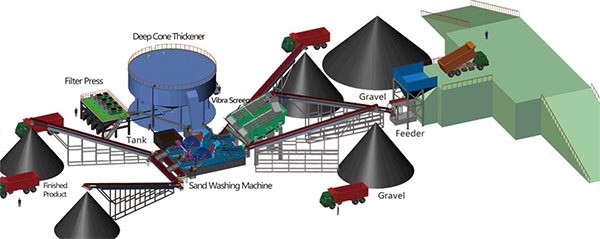

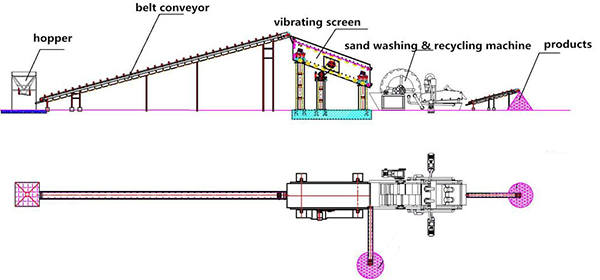

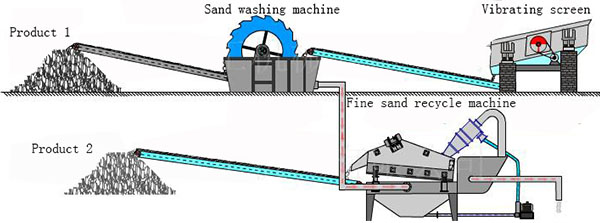

Sand washer machine layout plan is generally consists of sand washing machine equipment, waste water treatment equipment, waste water treatment equipment, conveying equipment, screening equipment, etc., which can be continuously adjusted, reduced or increased equipment according to specific requirements, treatment process and processing capacity. It brings together decades of experience in designing and providing production lines for customers.

Here are some common sand washer machine layout plan

1. Screening+sand washing+dewatering+fines recycling+muddy water purifying+sludge dewatering

2. Screening+sand washing+dewatering+fines recycling

3. Sand screening+sand washing+fine sand recycling machine

About sand washing equipment selection

1. For the selection of core sand washing equipment, the upgraded sand washing machine and waste water treatment equipment are recommended. Compared with traditional equipment, such equipment has been greatly improved in terms of sand washing, fine sand recovery, time-production capacity and even energy consumption. Moreover, such equipment is environmentally friendly.

2. For the selection of some auxiliary equipment, such as feeder, shaker, etc., the characteristics of materials must be treated before the purchase, such as: humidity, hardness, granularity, etc. Then according to the actual sand washing production line output value needs to select reasonable specifications of equipment, only in this way can better play its good auxiliary role, so that the effectiveness of the production line to achieve.

Some details about site planning

1. Arrange the storage area of raw materials and finished products reasonably. Generally according to the demand of finished products to arrange the production of stone washing machine, to prevent finished products in storage due to environmental or climate pollution, equipment before installation should be timely hardening of the ground.

2. Arrange the sedimentation tank, water supply, backwater and other pipelines of the sand washer reasonably. Keep the installation distance from the sand washer reasonable, without affecting the cleaning of the production site.

3. Lay the power supply line reasonably according to the demand, far away from the exposed water source, in order to ensure the safety of electricity use.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.