The Design of LZZG Spiral Sand Washer

The spiral sand washing machine is a kind of gravel cleaning production equipment which is associated with ore or gravel removing equipment, stone washing machine and crusher and sand making machine.Compared with roller sand washer and other types of sand washer, it has the feature of good cleanness and easy maintenance.

Spiral sand washer is used for the desliming and screening of the stone in construction site, sand and stone plant, prefabrication plant and water and electricity construction site, as well as for the grading of ores.

How is LZZG Spiral Sand Washer Designed?

The LSX series spiral sand washer manufactured by LZZG is designed to provide the most effective pool area and overflow speed requirements.

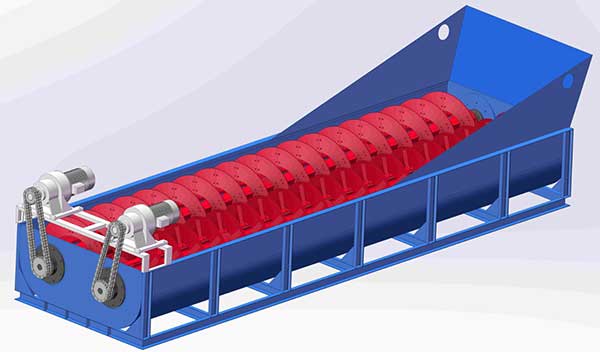

The proper combination of cell depth, area, and spiral structure is important to ensure controlled turbulence in the slurry stream to achieve accurate dimensional separation. The entire equipment is a box-shaped frame structure with a long body and a horizontal structure. It only needs a flat ground and a sewage reuse sedimentation tank.

The spiral sand washing machine does not require the use of a screen. The machine structure consists of a tank, a reducer, a motor, a central shaft, a spiral blade and a bracket. The bracket is welded on the central axis, and the spiral blades are tightened with bolts after being installed, so that the blades do not sag or deform. Below the water tank, three weir plates form a sedimentation tank, and the screw head is immersed in the tank.

The screw is driven by a motor and continuously rotates through a speed reducer. The spiral sand washing machine increases the width of the groove, increases the height of the overflow weir or decreases the inclination angle, so that the classification area is increased.

How Spiral Sand Washer Work?

During the operation of the equipment, as the impeller rotates slowly, the sand enters the washing tank from the feeding trough, and the screw device of the spiral sand washing machine continuously stirs the gravel material, so that the soil in the material is mixed with water and rubbed together to remove covering the impurities on the surface of the sand and gravel.

Adding water to form a strong water flow, taking away foreign matter with small impurities and small specific gravity in time, and discharging it from the overflow mouth washing tank to complete the cleaning effect.

The clean sandstone is taken away by the blade, and finally the sandstone is removed from the blade. The rotating impeller is poured into the discharge chute to complete the cleaning of the gravel.

Spiral Sand Washer Advantages:

- Long spiral shape, fully enclosed transmission, adjustable jaws, good sealing system.

- Simple structure, large feed, strong processing capacity and high washing efficiency.

- The moisture content of the sand is low, the mud content is low, and the output is large.

- Reasonable structural design, stable operation and convenient maintenance.

- The transmission device is separated from water and materials to reduce the failure rate, long service life and less wearing parts.

- The quality is firm, the fuselage is stable, the components are placed inside the equipment structure, and the noise is low.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.